As rail infrastructure across the United States ages under increasing freight demands and higher-speed passenger traffic, the need for smarter, faster, and more reliable inspection methods has never been more urgent. A cross-disciplinary team of Michigan State University (MSU) faculty, postdocs, graduate, and undergraduate students are answering that call with a breakthrough hybrid sensing system that could redefine how railroads detect and prevent failures.

Sponsored by the Association of American Railroads (AAR)’s Grand Challenges in Railroad Technology Program, and developed through a multi-year collaboration between MSU researchers, MxV Rail, and Adrian & Blissfield Railroad (A&B), the new system employs a multi-modal, non-contact method to identify surface and subsurface rail defects in real time, even at speeds up to 60 mph. It represents a significant advancement in safety, efficiency, and innovation for an industry that is the backbone of the American economy.

“We’re not just imagining the future of rail inspection,” said Dr. Sunil Chakrapani, an Associate Professor in the Department of Electrical and Computer Engineering, one of the project’s key lead researchers. “We’re building it right here at MSU.”

A Smarter Way to Inspect

Traditional rail inspection methods rely heavily on visual checks or contact-based sensors that struggle with accuracy at high speeds. MSU’s hybrid system changes the game. It combines:

- Motion-Induced Eddy Current (MIEC) sensing for electromagnetic testing

- Rayleigh wave EMATs for ultrasonic testing

- Laser-based ultrasound for non-contact, high-resolution inspection

This integrated design allows the system to detect both surface and internal defects without ever touching the rail. The shared magnetic circuit enables both sensing modalities to operate simultaneously, reducing footprint and improving efficiency.

“Our hybrid, multi-modal sensing system fuses data from electromagnetic and ultrasonic modalities,” said Dr. Yiming Deng, Principal Investigator of this multi-year AAR research grant and Professor in the Department of Electrical and Computer Engineering. Deng also leads the Nondestructive Evaluation Laboratory and is an affiliated faculty member of MSU’s Composite Vehicle Research Center. “This allows us to detect and localize rolling contact fatigue damage, including head checks and spalling, with high reliability and spatial resolution.”

Collaboration That Moves the Needle

The project began in response to a Grand Challenge issued by MxV Rail, a subsidiary of the Association of American Railroads (AAR). MSU’s proposal stood out for its interdisciplinary approach and practical potential and has since become one of the few university-led efforts still active in the program.

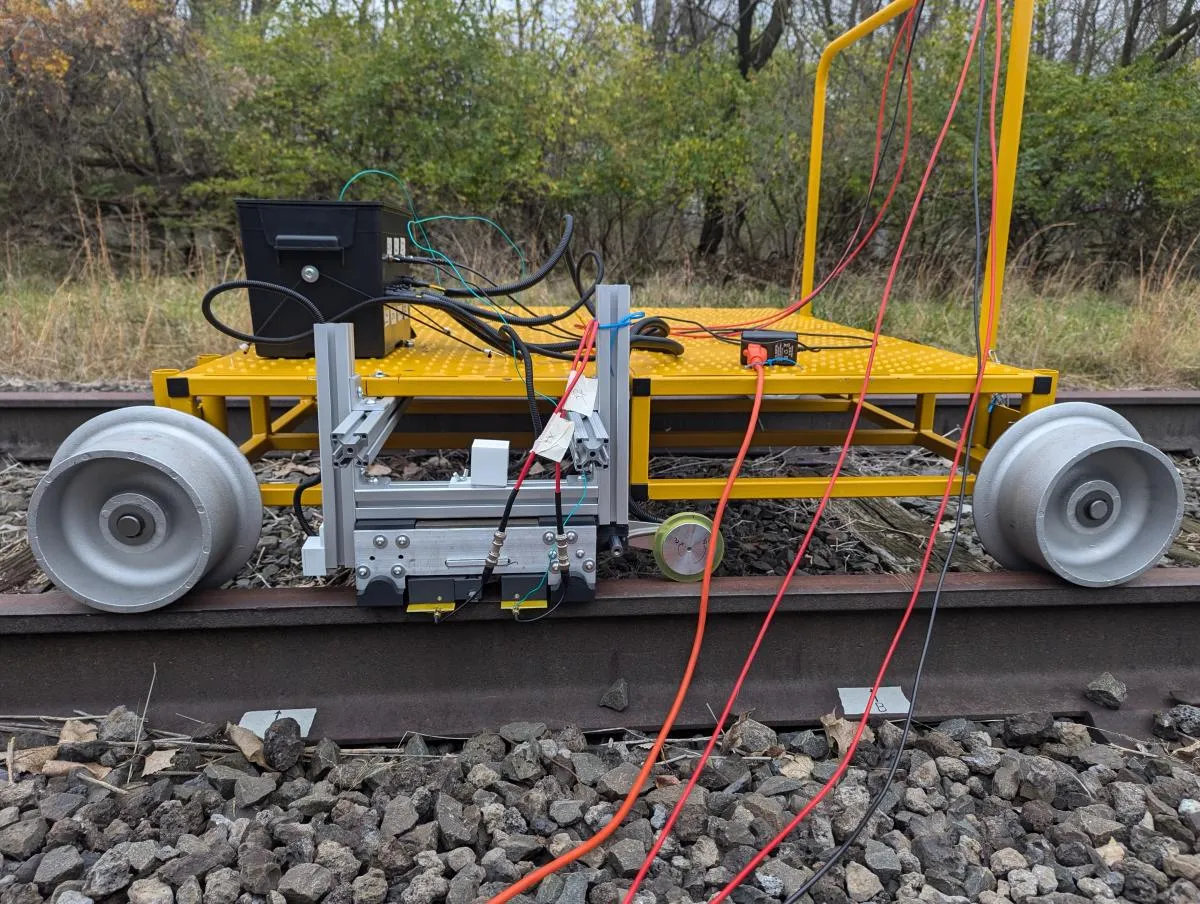

A&B Railroad played a pivotal role in bringing the technology out of the lab and onto the tracks. The company provided access to decommissioned rail lines for field testing and offered critical feedback on inspection priorities, defect types, and operational constraints.

“Very few times in a railroad person’s life do you get to help change the industry for the better,” said Chris Bagwell, President at A&B. “This collaboration with MSU is doing just that.”

The partnership was facilitated by Valerii Kucherenko, Director of MSU’s Center for Railway Research and Education (CRRE), which has a long history of connecting rail professionals with academic expertise. CRRE also runs a nationally recognized Railway Management Certificate Program, training current and future leaders in safety, operations, and innovation.

As the leader of the advanced Nondestructive Testing (NDT) and wayside inspection, detection, and analytics programs, focusing on research, development, and engineering solutions for MxV, Dr. Poudel’s insights and contributions provided the MSU team with essential industry knowledge. Serving as both Program Manager and industry Subject Matter Expert, Dr. Poudel played a vital role in guiding the MSU team, promoting innovation, and encouraging cross-disciplinary collaboration between MxV Rail and MSU.

From Lab to Field — and Back Again

One of the project’s most valuable lessons came from the transition from lab to field. What worked perfectly in controlled environments often failed under real-world conditions, from sensor misalignment to environmental noise.

“Translating a theoretically promising concept into a field-deployable system was one of our biggest challenges,” said Deng. “We overcame it through iterative design, prototype testing, and a novel data fusion framework.”

The team used 3D finite element simulations to model how motion-induced eddy currents distort magnetic flux signals at high speeds. These simulations revealed that subsurface defects are especially vulnerable to signal degradation — with peak-to-peak values dropping by over 70% at speeds above 50 mph.

To overcome this, MSU developed a Motion-Induced Eddy Current Array (MIECA) method using a U-shaped magnet configuration. This approach turns MIEC from a source of distortion into a positive excitation mechanism, improving sensitivity and enabling 2D imaging of defects.

Data Fusion for Precision Localization

The hybrid system doesn’t just detect defects; it locates them with remarkable precision. By combining ultrasonic transmission coefficients with electromagnetic signal peaks, the team created a spatial probability density function that pinpoints damage within 1 mm of its actual location.

“Neither UT nor EM data alone could achieve this level of accuracy,” said Dr. Ming Han, Professor in the Department of Electrical and Computer Engineering. “But together, they complement each other. One provides depth, the other provides location.”

This fusion of modalities is a significant advancement over traditional systems, which often struggle to balance sensitivity and resolution.

Powered by Partnership

The MSU Innovation Center has played a crucial role in turning research into real-world impact. From leading negotiations with industry partners and securing important sponsored research agreements, to supporting intellectual property filings and commercialization strategies, the Innovation Center has helped speed up the journey from lab to marketplace.

“The collaboration between MSU and Adrian & Blissfield Railroad is a prime example of how academic research, when applied to real-world challenges, creates impactful innovation,” said Brice Nelson, Director of Corporate Partnership at the MSU Innovation Center. “The MSU Innovation Center played a critical role in facilitating the partnership agreement, securing patents, and looks forward to continuing to support this talented team as they work to transform the rail industry.”

Dr. Deng also recognizes the important role of the MSU Innovation Center in enabling and supporting university-corporate partnerships. “The Innovation Center helped make possible our collaboration with industry partners, supported our technology transfer efforts, and assisted in filing our first U.S. patent,” said Deng. “Their support greatly accelerated our path from lab to field.”

Dr. Deng also offered advice for faculty considering industry partnerships:

“Start by listening. Understand the pain points your industry partner is facing. Align your research goals with their operational needs and be ready to adapt.”

Looking Ahead

With continued support from industry and federal partners, the MSU team is preparing for broader deployment on active rail lines. The goal: to make this technology a standard tool in the rail industry’s safety and maintenance toolkit.

Future iterations will include:

- Field-deployable hybrid probes with improved liftoff control.

- Real-time data processing and defect profiling.

- AI-driven modeling to predict defect geometry from sensor signals.

“We’re developing something that could be used across North America,” said Zebadiah Miles, a graduate researcher and Ph.D. candidate on the project. “And MSU is giving us the resources to make that happen.”

See additional information about MSU's Hybrid Rail Inspection System

Original Story courtesy of MSU Innovation Center

MSU College of Engineering Media and Public Relations page